At RuhrTech, our in-house manufactured Vacuum Insulation Panels (VIPs) set a benchmark in thermal protection, ensuring optimal performance even under the most challenging conditions. VIPs stand out, offering insulation efficacy up to tenfold superior to conventional insulation solutions. These panels are characterized by their impervious nature to gas and exceptional thermal insulation capacity.

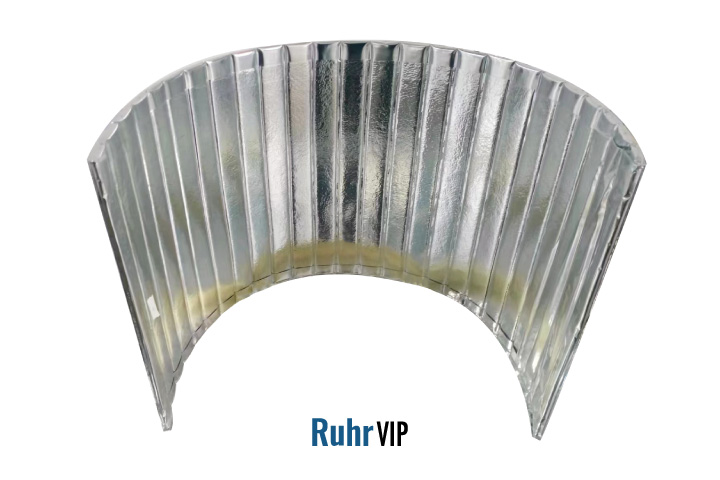

The heart of the VIP is a non-flammable, compressed fumed silica board. This core is enveloped and sealed with a robust gas-vapor-resistant film under a vacuum. This vacuumed state virtually nullifies gas conduction, giving VIPs their remarkable insulating properties. However, like all advanced technologies, VIPs come with their set of challenges. Over extended periods, there’s a risk of vacuum loss and potential unseen damage to the airtight seal.

Understanding these intricacies, RuhrTech emphasizes stringent quality control. We’ve pioneered a state-of-the-art quality control system, ensuring the integrity of the vacuum within VIPs can be assessed accurately in mere seconds. Furthermore, we’re committed to guaranteeing the highest standards in temperature-controlled packaging, instilling confidence in our partners and clients.

Insulation by vacuum insulation panels (VIPs)

Food-grade certified and eco-friendly internal coating

Multiple temperature ranges: fresh (0~8℃),frozen (-20~0℃), deep frozen (-50~-20℃)

Water-resistant and corrosion-resistant

Side handles for easy carrying

Increase payload with up to 68% space utilization rate

More lightweight reducing logistics cost

Washable with strong durability

Insulation by vacuum insulation panels (VIPs)

Food-grade certified and eco-friendly internal coating

Multiple temperature ranges: fresh (0~8℃),frozen (-20~0℃), deep frozen (-50~-20℃)

Water-resistant and corrosion-resistant

Side handles for easy carrying

Increase payload with up to 68% space utilization rate

More lightweight reducing logistics cost

Washable with strong durability

We eagerly await your feedback and inquiries!