Unveiling the Next Era of Innovation

RuhrTech’s R&D division stands as the beacon of evolution in the realms of insulation and cold chain materials. Harnessing the potent capabilities of Phase Change Materials (PCMs) and Vacuum Insulation Panels (VIPs), we’re constantly shaping the future, ensuring our partners in North America and Europe stay steps ahead in a dynamic market landscape.

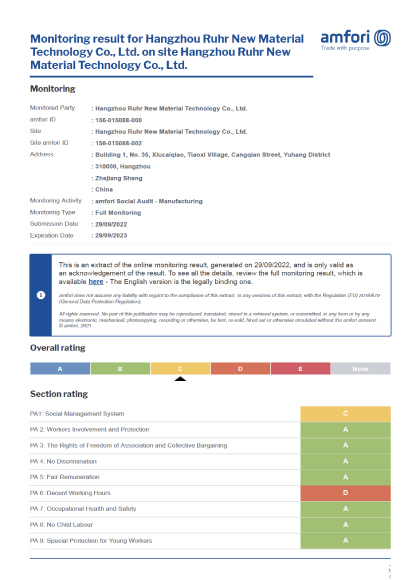

Passed

Passed

The RuhrTech Difference:

RuhrTech isn’t just about meeting standards; it’s about setting them. As we forge ahead, our partners can rest assured that they are aligning with a brand synonymous with future-ready excellence in insulation and cold chain solutions.

The RuhrTech Difference:

RuhrTech isn’t just about meeting standards; it’s about setting them. As we forge ahead, our partners can rest assured that they are aligning with a brand synonymous with future-ready excellence in insulation and cold chain solutions.

The RuhrTech Difference:

RuhrTech isn’t just about meeting standards; it’s about setting them. As we forge ahead, our partners in North America can rest assured that they are aligning with a brand synonymous with future-ready excellence in insulation and cold chain solutions.

Design qualification (DQ) involves establishing acceptance criteria that ensure the end-user’s original User Requirements Specification (URS) is met.

Operational qualification (OQ):

Summer profile test: min.load & max.load, 3 times each

Winter profile test: min.load & max.load, 3 times each

Mechanical Test: drop test, compression test, etc. ,following ASTM D4169

Performance qualification(PQ)