揭开创新的下一个时代

RuhrTech 鲁尔的研发部门是绝缘和冷链材料领域进化的灯塔。通过发挥相变材料(PCMs)和真空绝缘面板(VIPs)的强大功能,我们不断塑造未来,确保我们在北美和欧洲的合作伙伴在动态的市场格局中保持领先。

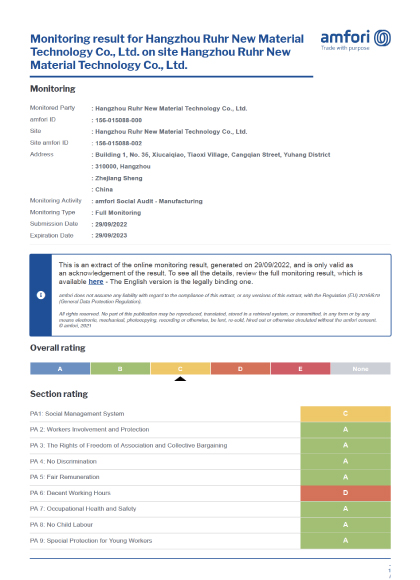

Passed

Passed

RuhrTech 鲁尔的区别:

RuhrTech 鲁尔不仅仅是满足标准;它是关于设置标准。随着我们向前推进,我们的合作伙伴可以放心,他们正在与绝缘和冷链解决方案的未来准备好的优秀品牌保持一致。

RuhrTech 鲁尔的区别:

RuhrTech 鲁尔不仅仅是满足标准;它是关于设置标准。随着我们向前推进,我们的合作伙伴可以放心,他们正在与绝缘和冷链解决方案的未来准备好的优秀品牌保持一致。

The RuhrTech Difference:

RuhrTech isn’t just about meeting standards; it’s about setting them. As we forge ahead, our partners in North America can rest assured that they are aligning with a brand synonymous with future-ready excellence in insulation and cold chain solutions.

设计确认(DQ)涉及建立接受标准,以确保满足最终用户的原始用户需求规格(URS)。

性能确认(PQ)